Summary of major crystal cuts

It is possible to define an infinite number of crystal cuts. However, some have defined properties that are particularly useful, and these cuts have been given specific names.

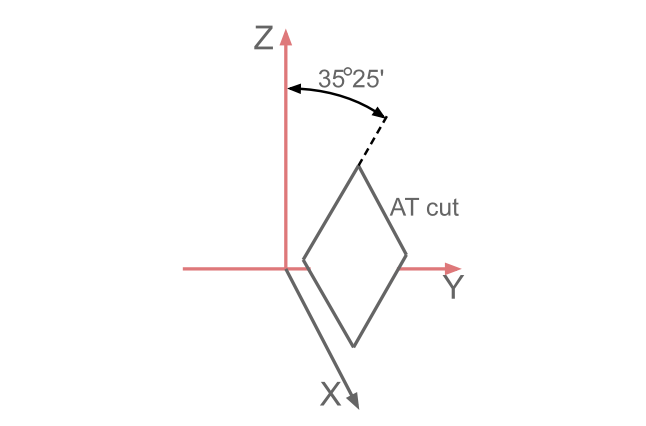

AT cut: The AT cut for quartz crystals is generally used for frequencies between 0.5 and 300MHz and it has a thickness shear mode of vibration.

It is the most widely used cut and it is particularly used for electronic instruments, etc where oscillators are required to run in the range 500 kHz to around 300 MHz, although the top limit is increasing as technology develops.

In view of its popularity and widespread usage more details of the AT cut can be seen below.

(Quartz crystal AT cut - 35° 35' to Z axis)

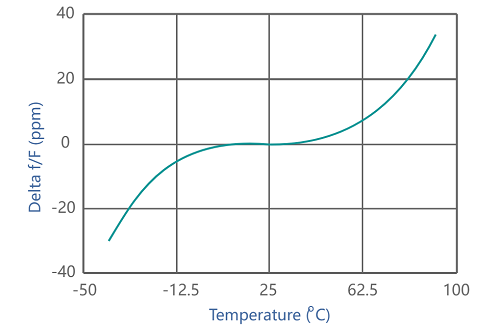

(AT cut crystal temperature coefficient with temperature)

BT cut: This is another cut similar to the AT cut which vibrates with a thickness shear mode and it is often used for frequencies from 0.5 to 200 MHz.

It uses a different angle: 49° from the z axis. It provides repeatable characteristics and has a frequency constant 2.536 MHz/mm. However the temperature stability characteristics are not as good as the AT cut, but it can be used for higher frequency operation more easily as a result of its higher frequency constant.

GT cut: The GT cut for quartz crystals is generally used for frequencies between about 0.1 and 2.5 MHz and it uses a width extensional mode of vibration.

It is cut at an angle of 51° 7', it has a temperature coefficient of nearly zero between +25 and +75°C as a result of the effect of the two modes of vibration having different temperature coefficient that cancel each other.

IT cut: This cut uses a thickness shear mode and is used for frequencies between about 0.5 and 200 MHz.

This crystal cut is very similar to the SC. However, with crystal ovens needing to work in the range 80 - 90°C this option has enabled the difficulties using the SC at these temperatures to be overcome. The IT cut has a upper turning point of between 85 and 105°C but it does not share the lower level of mechanical stress sensitivity of the SC.

SC cut: This crystal cut is used for frequencies between about 0.5 and 3200 MHz.

This cut was developed in the late 1970s especially for use in precision crystal ovens but it does require a more complicated manufacturing process because a double angle rotation is required along with precision lapping later.

XY cut: This cut is essentially a crystal cut format used for low frequency applications for frequencies typically between about 5 and 100 kHz. It uses a length-width flexural mode.

This crystal cut is widely used for low frequencies where one common frequency is 32.768 kHz. It has advantages that it is very small for the frequency, is less expensive than other low frequency crystal types and in addition to this it has a low impedance and low Co/C1 ratio.